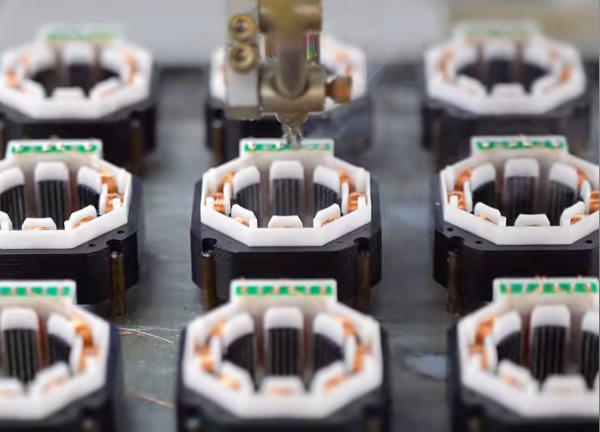

The open-loop two-phase hybrid stepper motors of GRMOT feature a step angle of 1.8°, high torque, low noise and precise positioning, combining the advantages of permanent magnet and variable reluctance types. GRMOT’s hybrid stepper motor drivers offer strong anti-interference capability and are compatible with pulse signal speed regulation. Widely applied in industrial scenarios such as 3D printing, CNC equipment and automated assembly lines, they ensure efficient and stable operation of devices.

View Details

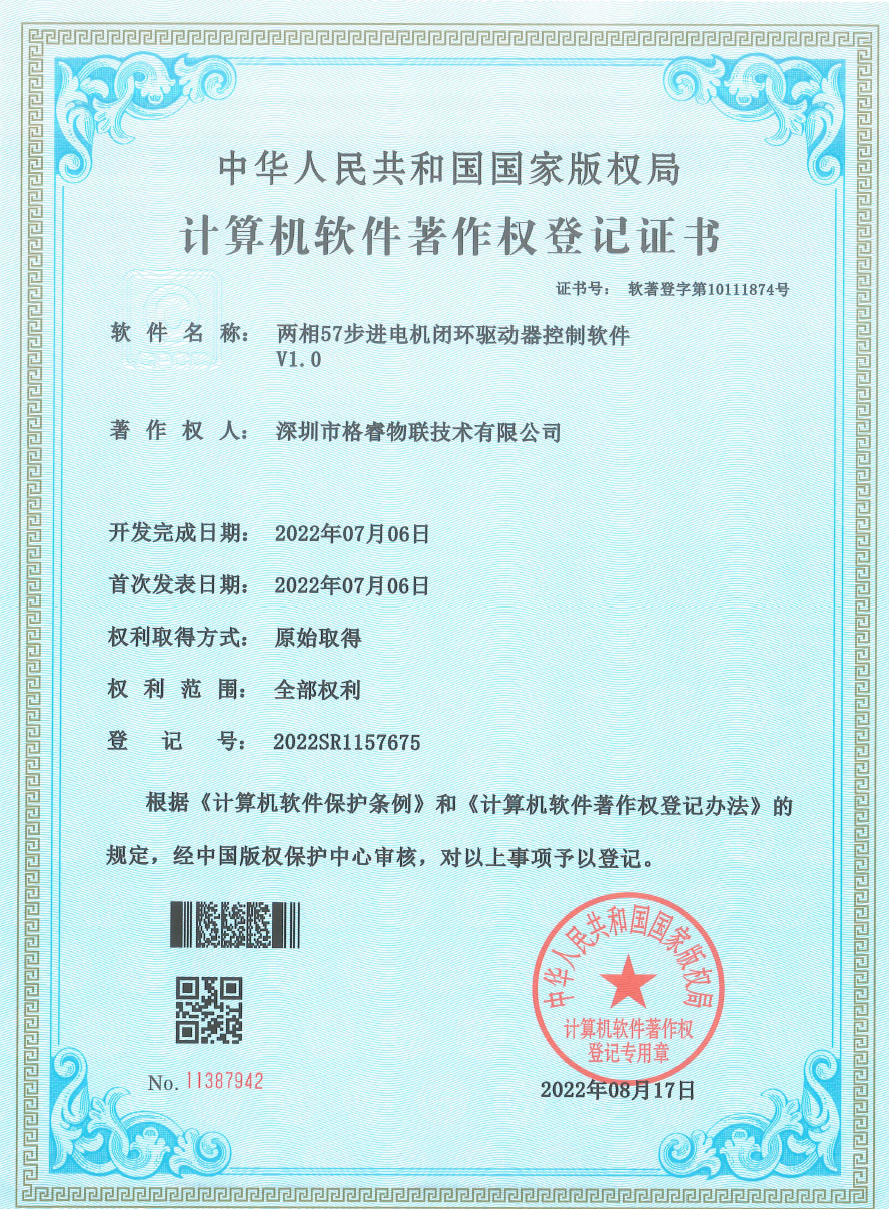

The closed-loop stepper system adopts the latest dedicated motor control DSP chip and vector closed-loop control technology, completely overcoming the step-loss problem of open-loop stepper motors. At the same time, it significantly improves motor high-speed performance, reduces motor heating, and minimizes motor vibration, thereby enhancing machine processing speed and precision, and reducing machine energy consumption.

View Details

RS485 and EtherCAT bus-type drivers feature easy networking and wiring, enabling high-speed, real-time, high-precision, and multi-axis synchronous motion control solutions.

View Details

With the electro-mechanical design of the latest engineering and manufacturing technology, GRMOT’s servo motors with encoders combine excellent dynamics and torque accuracy. They feature low torque ripple, minimal temperature rise, high power density, and high overload capacity.

View Details

Brushless DC motors use electronic commutation, offering high efficiency, energy saving, low noise, and long lifespan. They are widely used in home appliances, new energy vehicles, and industrial automation.

View Details

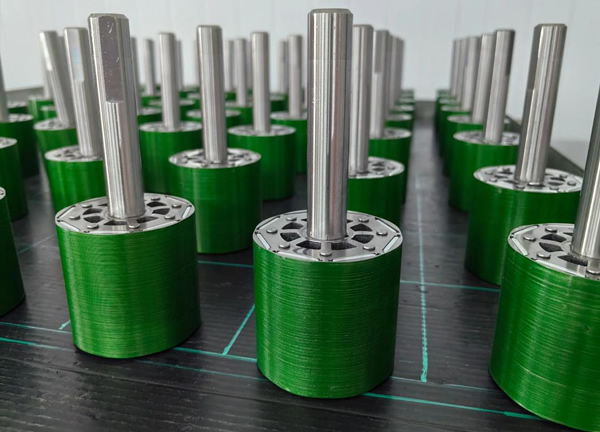

The iSS series intelligent integrated hybrid servo motor integrates high-performance stepper motor, encoder feedback, closed-loop vector control drive, and network communication module and technology into one unit. It is compatible with the dimensions of traditional stepper motors in installation, combining the dual advantages of stepper technology and AC servo. Moreover, it eliminates the need for a large number of connecting cables between the motor and the drive, between the encoder and the drive, saving a significant amount of wiring labor, reducing electromagnetic interference between wires, and lowering the reliability issues and maintenance costs caused by a large number of connectors and unreliable connections between wires. Of course, it also reduces the space occupied by the drive. The iSS series adopts low-heat generation technology and anti-vibration design, providing revolutionary new technologies, products, and solutions for your equipment upgrades.

View Details

The electric drum features a compact structure, high transmission efficiency, stable operation, and easy maintenance, and is widely used in automated conveyor lines, logistics sorting, and packaging equipment.

View Details

The stepper motor torque and speed modulation driver can flexibly adjust torque and speed, is easy to apply and has high precision, and is widely used in die cutting, web handling, and multi-axis linkage scenarios.

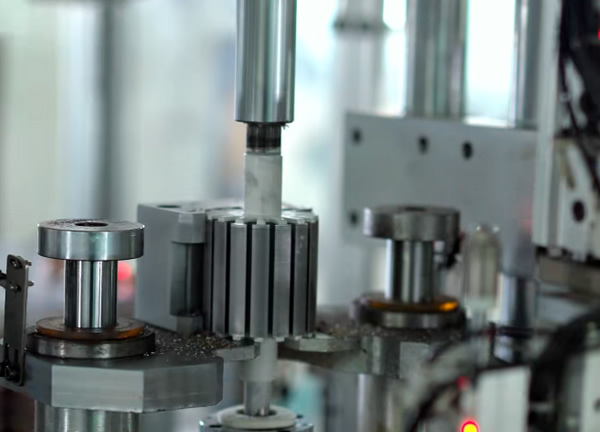

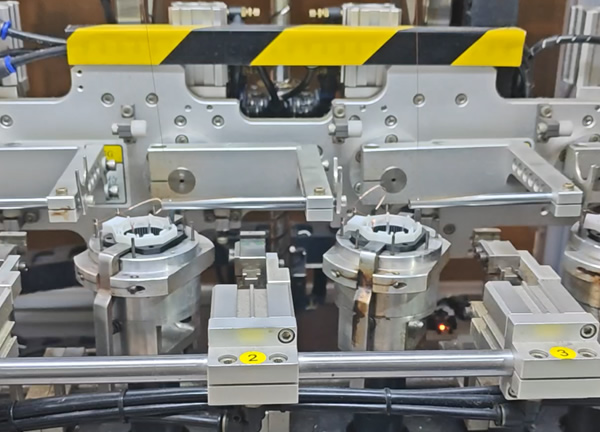

View DetailsWe possess advanced production lines and complete equipment sets, relying on deep technical accumulation to ensure every product reaches high-quality standards.