Differences Between Coreless Motors and Conventional Motors

The differences between coreless motors and conventional motors mainly lie in structure and application. Structurally speaking, a coreless motor is a special type of motor composed of an outer frame, drive coils distributed along the periphery, a hollow rotor in the middle, and attached sensors. The name “coreless motor” derives from the design of its rotor component.

· Differences Between Brushed Coreless Motors and Conventional Motors

· Differences Between Brushless Coreless Motors and Conventional Motors

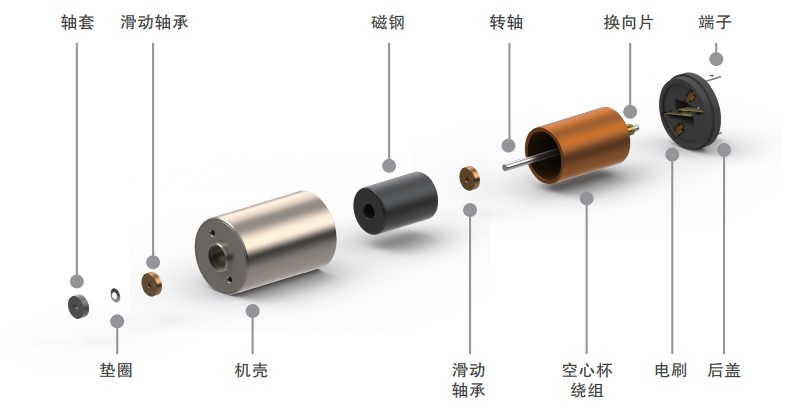

· Structure Diagram of Coreless Motors

The rotor of a coreless motor breaks through the rotor structure of conventional motors, adopting a coreless rotor with a hollow cup-shaped structure. The interior is surrounded by windings and magnets. This rotor structure eliminates electrical energy loss caused by eddy currents in the iron core, while significantly reducing the rotor’s weight and moment of inertia, thereby cutting down the mechanical energy loss of the rotor itself.

The structural differences between coreless motors and conventional motors are as follows:

1. Different Structures: The rotor of a coreless motor is a hollow cup-shaped structure, whereas the rotor of a conventional motor is solid.

2. Compact Size: Thanks to its hollow cup-shaped rotor structure, a coreless motor can be designed with a more compact overall size. Compared with a conventional motor of the same power rating, a coreless motor occupies a smaller volume.

3. Lightweight: The structural design of coreless motors makes them extremely lightweight, making them suitable for applications with strict weight requirements.

The application advantages that distinguish coreless motors from conventional motors are as follows:

1. High Power Density: Due to their small size, coreless motors feature higher power density, meaning they can deliver greater power output per unit volume.

2. High Efficiency: Coreless motors have a compact structure and short magnetic circuit, which minimize iron core and copper core losses, resulting in higher energy conversion efficiency.

3. High Precision: When paired with high-resolution encoders, coreless motors can achieve ultra-precise position control.

4. High Integration: Coreless motors are often integrated with built-in sensors (e.g., encoders), enabling real-time monitoring of the rotor’s position and speed.